First, an overview

As a thermal power machine, hot air stove is widely used in our country. It has become a replacement product of electric heat source and traditional steam heat source in many industries. It has the characteristics of stable, reliable, safe and efficient. Through production practice, it has been realized that only by using hot air as medium and carrier can the thermal efficiency and thermal work effect be improved greatly.

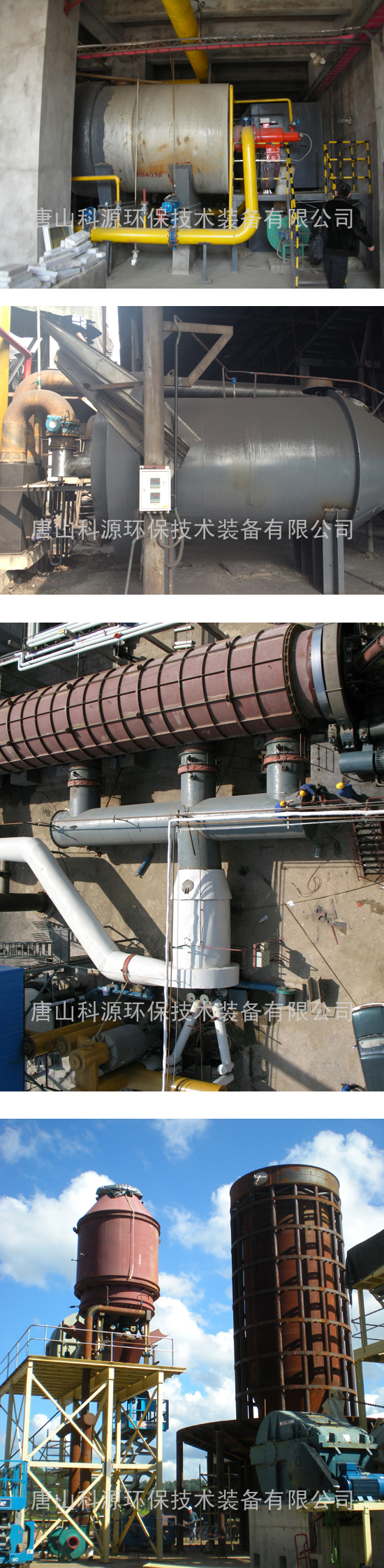

After years of practice, the coyuan company developed and designed a hot blast stove and its combustion system. Through the test of hot air temperature, the fuel consumption is constantly adjusted and the utilization rate of fuel is high. The high temperature gas obtained after the combustion of the fuel needs mixing part of the air and mixing it into the drying room or baking room directly after a certain temperature of the production. It is contacted with the dried material, heated and evaporated, so as to obtain the dry product. The consumption of fuel by this method is about half as much as that of steam or other indirect heaters.

Two. Application examples

The hot blast furnace combustion system developed by coyuan company is suitable for all kinds of drying kiln, heat treatment line, cleaning coating line, annealing furnace, tunnel kiln and other production lines, which can fully meet the requirements of temperature, safety and environmental protection of the above equipment. At present, there are successful cases in many industries, and considerable economic benefits have been achieved.

Three, the application range of hot blast stove

1. Preparation and drying of chemical products, chemical products and pharmaceuticals in chemical and pharmaceutical industries.

2. Baking paint, powder spraying and curing of industrial products such as automobiles, motorcycles, containers, household appliances, tin cans, etc.

3, textile printing and dyeing and non-woven industry heat setting, hot melt dyeing, baking, hot air stretching.

4, casting industry sand and sand core drying.

5, grinders, abrasive industry sand cloth and grinding wheel drying.

6. Wood drying, artificial board, laminate drying, gypsum board drying, and drying of fiberglass products in building materials industry.

7. Drying of roasted coffee, tea, tobacco leaves and vegetables, cereals, noodles, aquatic products, fish meal and soybean meal.

8, heating engineering industrial buildings and civil building heating.

9, welding material industry welding rod, flux drying.

10, insulation materials, FRP Industry aluminum silicate fiber products, rare earth insulation, FRP products drying.

Four. System characteristics

1. full combustion, no black smoke in hot air, clean operating environment, environmental compliance, no two pollution.

2. high cleanliness of hot air and low dust content.

3. hot air temperature adjustment is convenient, continuous heating air temperature is stable.

4. the equipment has high safety, no explosion and other dangers.

5. the equipment has strong durability, low running cost and simple maintenance.

6. all the hot air enters the drying equipment, and the production process does not increase the discharge port.

7. configure fire detector to prevent gas from extinguishing danger.

Five. Safety maintenance of hot air furnace

1. when the hot air stove is overhauled, the blind board or other reliable cutting devices are used to prevent the gas from channeling from the adjacent gas pipeline and the operating card system is strictly enforced; the gas protection personnel should be monitored on the spot.

2. during the maintenance and cleaning of hot blast stove, the following rules should be observed.

3. the gas pipeline should be blind, and all valves except the flue valve should be shut off and cut off the power of the valve.

4. furnace should be well ventilated, the concentration of carbon monoxide should be below 24ppm, the oxygen content should be between 18% and 21% (volume concentration), and each 2H should be analyzed once.

5. when repairing the partition wall of hot blast stove, the steel can be used to support the shed to prevent the upper brick from falling off.

6. when hot air pipes are overhauled, they should open manholes to prevent gas hot air from entering.