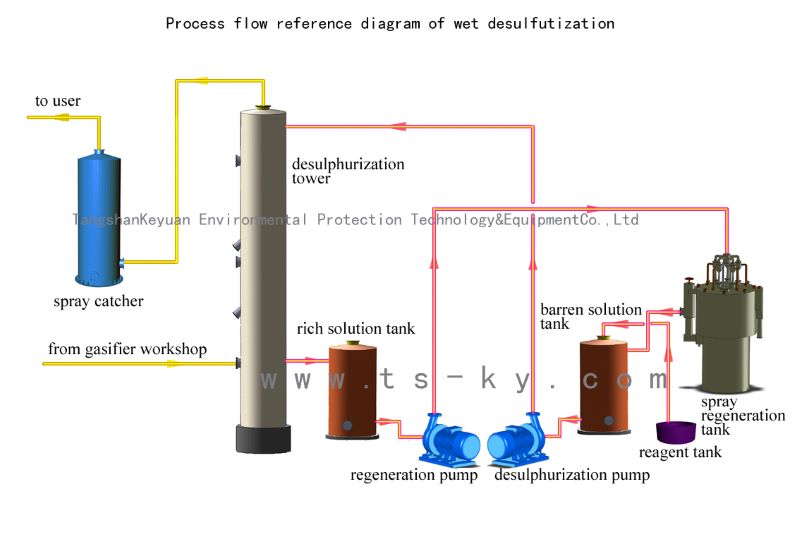

Process flow:

Gas containing H2S enters from the lower part of the desulfurization tower and reacts with the desulfurization lean liquid sprayed at the top of the tower in the packing layer to absorb and remove H2S. The purified gas is discharged from the top of the desulfurization tower, and then excess water is removed in the droplet trap before being sent to the workshop for use. The solution leached from the top of the tower absorbs H2S and flows into the rich liquid tank for sulfur evolution. It is then pumped through a regeneration pump to the jet regeneration tank for reaction with air. The solution is oxidized and regenerated before flowing into the lean liquid tank through a liquid level regulator. It is then pumped into the desulfurization tower through a desulfurization pump for continuous desulfurization. At the same time, the sulfur foam generated in the injection regeneration tank overflows to the foam pool for filtration, and the sulfur paste is filtered out.

Applicable scope:

Suitable for the purification and desulfurization (removal of H2S) of producer gas, coke oven gas, blast furnace gas, biogas, and urban gas.

Features:

The gas purity can be adjusted according to actual needs, and the H2S content in the gas can be smoothly controlled.

Compared with dry desulfurization, the operating cost is slightly lower, avoiding the problem of increased production costs caused by poor desulfurization effect and sulfur adsorption after desulfurizer regeneration in dry desulfurization systems.

Compared with other wet desulfurization methods, it has the characteristics of stable operation, safe operation, and high desulfurization efficiency. The desulfurization efficiency can reach over 97%, and the hydrogen sulfide content in the desulfurized gas is less than 50mg/Nm3.