Biogas, as an emerging energy source, is increasingly being used in various industries. However, the sulfur content of biogas is very high, and the national standard strictly stipulates that the sulfur content of biogas during the trial period should be less than 20mg. Therefore, biogas must be desulfurized before it can be utilized.

The commonly used methods in the industry are dry desulfurization, wet oxidation regeneration desulfurization, biological desulfurization, etc. Among them, wet oxidation regeneration method is the most mature and reliable. When special industries require low hydrogen sulfide content, wet and dry desulfurization can be combined to ensure stable desulfurization effect.

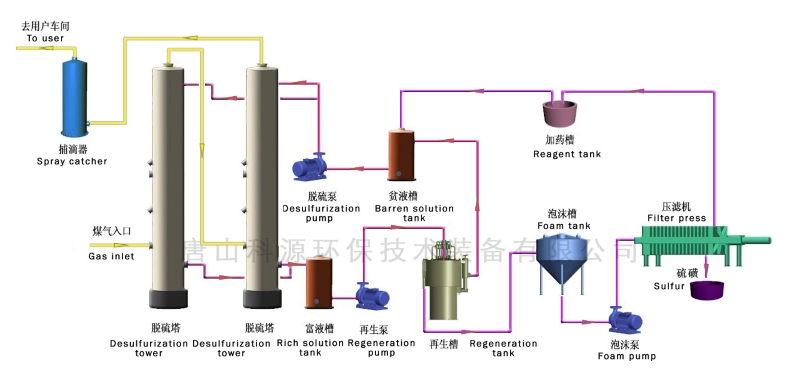

The wet oxidation regeneration method for biogas desulfurization uses an alkaline solution as an adsorbent, which absorbs H2S under the action of a catalyst and converts sulfide into elemental sulfur. The reaction process is that the desulfurization solution is sprayed from the top of the desulfurization tower, and the biogas containing hydrogen sulfide enters from the bottom of the desulfurization tower. The biogas and desulfurization solution come into reverse contact, producing oxidation reaction in the desulfurization tower and producing elemental sulfur. The desulfurization efficiency can reach 99%.

In response to the presence of carbon dioxide in biogas, the system will control the consumption of alkali solution by controlling the reaction conditions (temperature, pH), while ensuring stable desulfurization effect.